Designer Solution

How to making

Shoe Prototype Making

Designer solutions

How to making

Shoe Prototype Making

HOW WE MAKE PROTOTYPES

Bring your designs to real with THE K FAMILY FACTORY Prototyping development. This step is the most important to develop a new shoe collection before making a production order.

Our team will transfer your designs to physical prototype sample once all details confirmed, you can check the fit, outlook and look into more details regarding your designs by physical samples before sales sample manufacturing.

The prototyping process is consisting of material and heel selection, shoe last creating, 2D pattern making, development of custom moulds for metal, rubber or heel components if needed, and creation of hardware elements and embellishments as required. As a shoe manufacturer with decades of experience in this space, we will work with you from the initial idea to final product and beyond no you can focus on growing and expanding your brand.

HOW TO MAKE SHOE PROTOTYPE?

MATERIAL SELECTION

Material selection is the basic for shoe prototyping. Outlook of each shoe style is depends on what material used. Material quality, texture and hand feel are all need to be taken into consideration.

K SHOES FAMILY FACTORY focus on hand-made high quality products for our clients. Every made-to-orderpair of shoes made from K SHOES is built with the finest materials. We have full range of colors and textures for every type of footwear to select, vegan leather, recycle leather, genuine leather, metallic leather, suede, special materials, exotic skins and fabrics in different quality, color and texture. K SHOWis also open to customized material, like print material with customer artwork, special texture leather and hand-weave, hand beading uppers. Each hide and piece of material will be inspected by our workers before making on shoes to ensure its quality.

HEEL SELECTION

Heel is essential for women’s shoes and play an important role on shoe making process. Shoe last will be created on the base of heel. Different heel shape will come to different last curve, it is crucial to select correct heel shape and height before creating shoe last.

THE K FAMILY FACTORY is with a large number of heel shape and height available in different materials. We have ABS heel, which is most common used because it Is light-weight and inexpensive, ABS heel could be made to leather covered heel, coating heel, print heel. Other heel material like metal heel, resin heel and handmade wood heel are also available in our show room. Clients can select whatever they want as per design.

K SHOES FAMILY FACTORY is open to Customized heel mold. When special and unique heel shape, or heel with brand logo was designed, customized heel mold is a best option, our technician will make 3D drawing as per the design spec for customer to approve the general outlook and construction of heel. Once 3D drawing approved, then customized heel mold could be produced. Customized heel mold couldn’t be changed, no matter in height or shape once finish.

SHOE LAST CREATING

Shoe last is the form that shoemakers use in shoe molding and it is the anatomical “copy” of our feet. Shoe last comes in different forms, shapes and are made from different materials, there are three kind of materials Wood, Plastic and Aluminum, most common used material for us is plastic. Last is used only in shoe making. It is the first “tool” that we are using in making of shoes and we will be using it through the entire process of shoemaking.

Last creating is to transfer your design to a foot mold, A completed shoe last should give you a clear idea of what shoe lasts look like upon completion. Women’s shoe last is normally created based on heel shape and shoe style. Different shoe style construction will be with different last shape, Take thong sandal and pump styles for example

Thong sandal, It is open In the toe, in the instep and heel part, and most of them have fastening in the ankle area. Pumps are constructed in the way where they sit tightly on your feet and without any fastening.

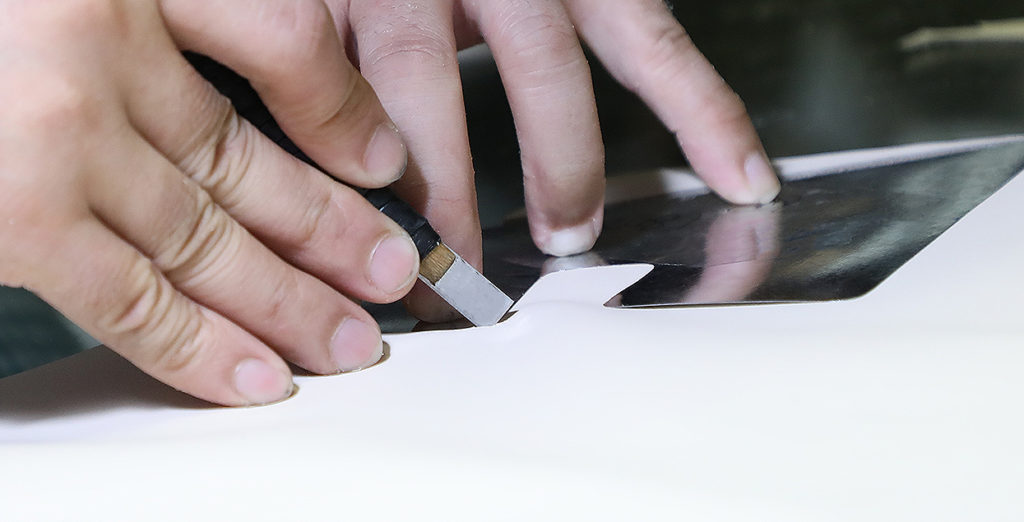

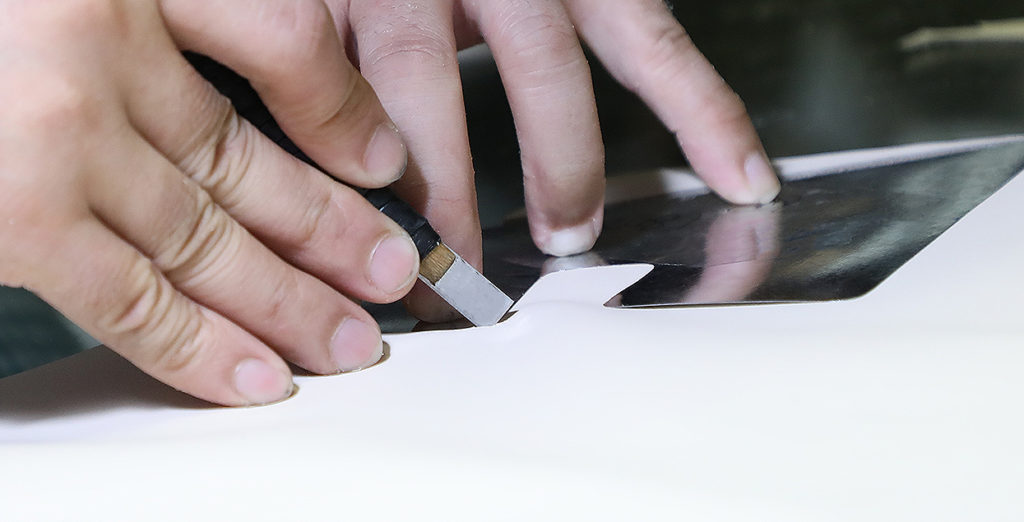

2D PATTERN MAKING

When shoe last created, the next step is pattern making.

Pattern making is the process of creating the ‘Project’ of the shoe upper made by the various parts of upper and lining. Pattern making also extends to other components, such as the insole, heel and wedge covers or other components in case of particular shoe constructions.The pattern maker need to hand sketching the shoe design line on shoe last or on paper and convert it into a series of 2D shapes, we call it pattern pieces, Patten piece is essential during whole shoe making process.

Initially, patterns are made in one size (the sample size) for prototype only and then they are ‘graded’ (made smaller and bigger) to cover the full size range of shoes for SMS sample or production. It is important to say that only the size of every piece will vary, while the design will never change.

Prototype sample will be made after pattern finished. It is a trial sample for fit, pattern and construction checking, Prototype sample could be made with available color in correct material quality.