Designer Solutions

How to making?

Bag Making Progress

Designer Solutions

How To Making ?

Bag Making Progress

Bag, which is daily needed for peoples in different roles, you could see it everywhere.

Bag is also very important to a woman, it could be a decoration sometimes to match with your suit or dress.

A beautiful bag will make you more confident and attractive.

THE K FAMILY OF BAG TEAM focuses on details because they strengthen the product without interrupting the wearability. Details like leathers, hardware, stitching, handmade, ethical manufacturing process, contrast leather and stitching in various thickness, length and colour, add value and function to the design. besides handmade craftsmanship bags, we also research new ethical materials, new ethical bags.

Hardware selection and creation

Hardware is the most important part for bag. It could be functional or decoration. An eye-catching hardware could be the soul of a bag, it can improve the outlook of bag and also attract more people to buy it.

THE K FAMILY FACTORY is with full range of hardware shape and size available. It could be round, square, and other special shape. Hardware material could be metal, resin, wood and plastic.

For colors, it could be leather covered, coating or plating colors. You can choose whatever you would like.

THE K FAMILY FACTORY is also open to customized hardware, and most customers will do customized hardware for their bags, such as a metal brand logo or some special elements could stand out the specialty of their brand. All we need is a hardware spec with overall shape, measurement for each part, such as width, length and thickness. We will make a 3D drawing to confirm the outlook and structure and then proceed making correct hardware mold once 3D drawing approved.

For bag types, there are several different type of bags for women, such as tote bag, shoulder bag, clutch and so on.

Tote Bag

The features of Tote Bags is large and easy to carry, it is very popular among teens and women. Tote bag is with wide straps and a zipper on top for security and privacy . Tote bag is big enough to hold all daily supplies like a small make-up bag, water cup, umbrella, laptop and others, it’s a good option for travel or office.

Shoulder bag

Shoulder bag is one of the popular types of handbags for women. It maybe with a single or double strap which is long enough to be carried over the shoulder. It comes in different sizes, which are smaller than tote bag, Should bag is also a good option to match with different type of clothes, like T-shirt or dress.

Clutch

Clutch, also called envelope bag, it is with a small size bag that can be held on hand. Clutch is often used as a decoration due to its small volume. It is often used to match with evening dress.

How to Making Bag?

Although there are different kinds of bags, the manufacturing process are the same for all.

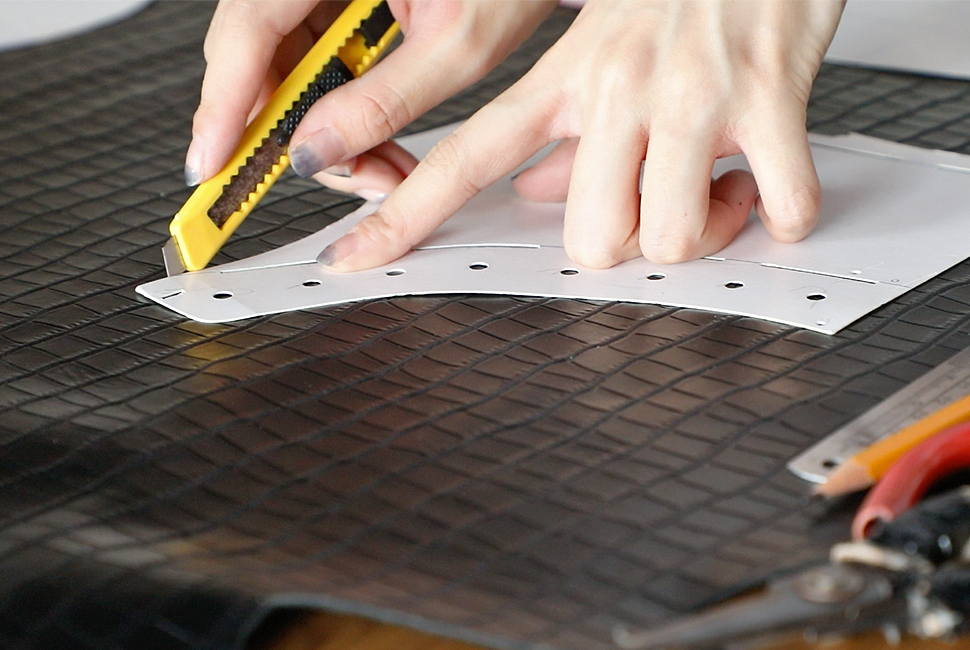

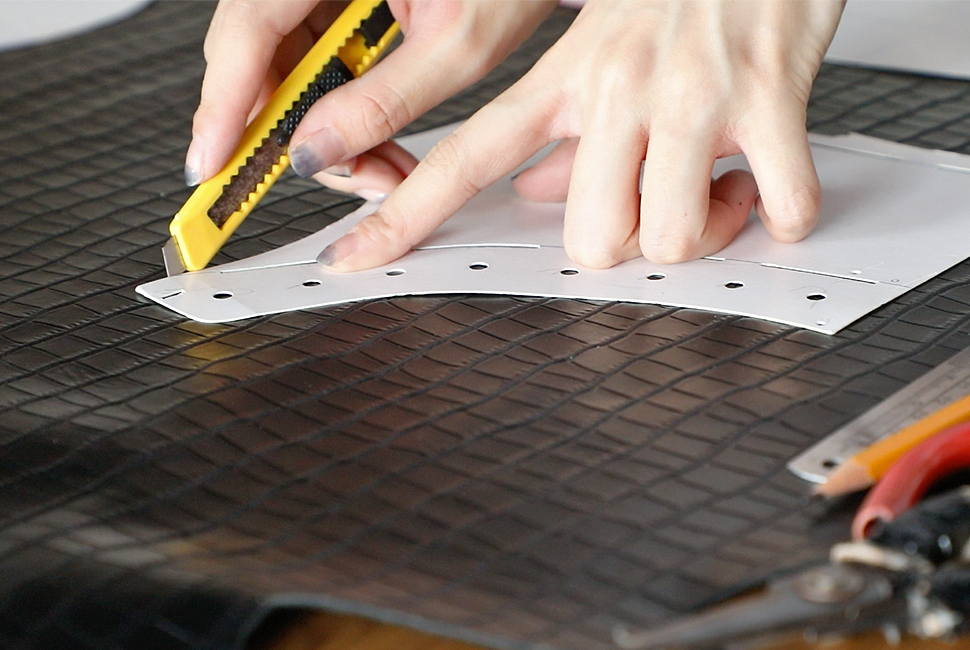

Cutting Materials

The bag making process starts with cutting materials. All production materials will be confirmed before production

Bag parts are generally hand-cut into different pieces, every part for every size needs its own pattern pieces.

On this stage, material usage and wastage is the most important that need to be controlled, our workers are with decades of cutting experience, they have a good knowledge on how to cut the shoe uppers with the most usage and less waste

Besides material cutting, some hand-work like skive edges, gauge marking are finished here before moving to stitching department.

Technology like print, stamp or embroidery are made after cutting finished.

Stitching bag

Once the bag parts are cut, the stitching department takes over.

In the stitching department, the operations are divided into simple steps, leather pieces are stitched together. First the upper, then the lining. For some bags with strong and hard shape, we need to insert cardboard inside for overall shape.

In the stitching department, the operations are divided into simple steps, leather pieces are stitched together. First the upper, then the lining. For some bags with strong and hard shape, we need to insert cardboard inside for overall shape..

In order to prevent the leather pieces off position during operation, Stitching workers usually attach one to one another at the edges with glue. First, the upper is stitched together, followed by the lining. After both upper and lining have been stitched together, the seams are neatened and loose thread are trimmed.

Attaching the straps and decorate elements

After stitching of bag body finished, then move to last step, attaching the strap and embellishments.

The straps of the handbag can be made of different materials like metal, leather or resin, it can be detachable or not., which depends on your bag construction. For example hand bags often with strap made by upper leather, evening bags often have metal chain straps. If the strap is made of a metal chain, the chain is usually attached to a metal ring. If the strap is made of leather, the manufacturer usually cuts two identical, long pieces, which are folded over one another and stitched together. The leather straps can be stitched to the sides of the handbag or they can be attached to metal rings. Handmade bags usually have very durable straps made of leather or a durable metal. The last part of the handmade handbag making process is to sewn all sorts of decorate elements, such as beads, clasps, etc into bag, then a complete bag finished and ready for inspection.

Quality Control

When a complete bag finished, it will be cleaned and trimmed, then ready for inspection

Quality control is a process which customers seek to ensure that product quality is maintained or improved. THE K FAMILY FACTORY team will do quality control for all products made, some of our clients will assign a third-party for final inspection after production ready.

Quality control help you determine the overall quality of your order, and determine the need to issue corrective actions before any products leave the factory. It also minimizes the amount of costly product defects. Inspections can detect merchandise containing non-standard or non-compliant components.

THE K FAMILY FACTORY team recommends the International Inspection Standard to determine the number of units that will be randomly selected for evaluation. Shoes are checked against a detailed inspection plan for appearance, applicable functionality, packaging integrity, workmanship, and your specific requirements. Discovered defects are classified as major, minor, or critical depending on inspection plans. If you have your QC standard and procedure, we will concern to follow your documentation.

And there are several types of inspections available throughout the production process. In-Process and Pre-Shipment inspections. As one of the longest serving inspection companies in Asia, one of our Inspection Manager are very capable to help choose the best source inspection service to fit your requirements.

PACKING

Once Inspection finished and approved for shipping, our workers will each bags with dust-bag and Bags will be shipped with carton.

Each bag is stuffed tissue paper inside to keep the bag shape and some anti-mold desiccant will be included inside the bag to prevent it from moldy. The same style bag will be packed in the same carton. Packing requirement varies from brand to brand, product to product, it provides protection against atmospheric moisture, dust, damage, shocks.

Quality, respect and an ethical approach to manufacturing in THE K FAMILY FACTORY is an integral part of our DNA. All our products are made using ecologically friendly materials and sustainable processes.

THE K FAMILY FACTORY are ready to accept your requests in terms of product customization, sizing and monogram printing, offering a unique and exclusive specialized assistance.

THE K FAMILY TEAM is happily working with new designers. Working together, Create new bag line.