Designers Solutions

Designers Solution

Fashion Show Shoes Development

A fashion show is an event put on by a fashion designer to showcase their upcoming line of catwalk shoes and accessories during Fashion Week. Fashion shows debut every season, particularly the Spring/Summer and Fall/Winter seasons. This is where the latest fashion trends are made. In a typical fashion show, models walk the catwalk wearing the shoes and accessories created by the designer. It is then up to the audience to not only try to understand what the designer is trying to say, but also to visually deconstruct each outfit and try to appreciate the detail and craftsmanship of every single piece. A fashion week is a fashion industry event, lasting approximately one week, where fashion designers, brands or houses display their latest collections in runway fashion shows to buyers and the media. These events influence trends for the current and upcoming seasons. All high end designers are pursuing collaboration with a manufacturer that understands the high end market.

THE K HANDMADE FAMILY FACTORY, founded in January of 1999 and based on the idea that solving global Ready-To-Wear and Haute Couture designer’s problems, provides you with no minimums requirement, made to order, handcrafted skill, world class quality and service, who also has its own R&D core to do design, development, manufacturing and quality control for global Ready-To-Wear designers. My family factory is very interested in developing new catwalk shoe styles for your coming seasons, enriching your catwalk shoe lines and enhancing profit for you.

Our family factory makes catwalk shoe samples each season and run production orders after fashion show weeks. We have the most experienced team, finest leather factory and hardware factory to offer unique solution for your catwalk shoe and accessories project. You can design new catwalk shoes and accessories with your logo, and our sample room is able to make new prototype from your drawing specs with ethical operations.

THE K HANDMADE FAMILY FACTORY has the ability to transform your ideas to reality, making your designs adorable and gorgeous. To start new projects, you can do prototype and samples first, use new samples as preorder, put them on showroom, do photo shooting on magazine, show them to buyers, and then bring your design to the market. A pair of remarkable catwalk shoes are developed by the following steps in our family factory:

1. CATWALK SHOE DESIGN CONCEPT

If you are starting your own private label you will need assistance from prototype to the finished product. And first up is the catwalk shoe design concept. Once the design concept has been selected and refined, it is time to turn the drawings into a sample or a prototype of a pair of new catwalk shoes. This is when we join the designer to move the project forward. Together, the catwalk shoe designer and our factory will create a detailed ‘tech pack’ or a set of specification drawings or for the new catwalk shoe design, which detail every part of the shoes from the upper to the outsole bottom, including the name of each shoe part, the material, thickness, and color. The spec also includes the catwalk shoe last information, logo art, design details, emboss effects etc. Sometimes it may include sample shoes, material swatches, photos, or any other notes to help build the samples. The catwalk shoe development spec may be e-mailed, sent by courier service, or hand carried by the developer to the factory.

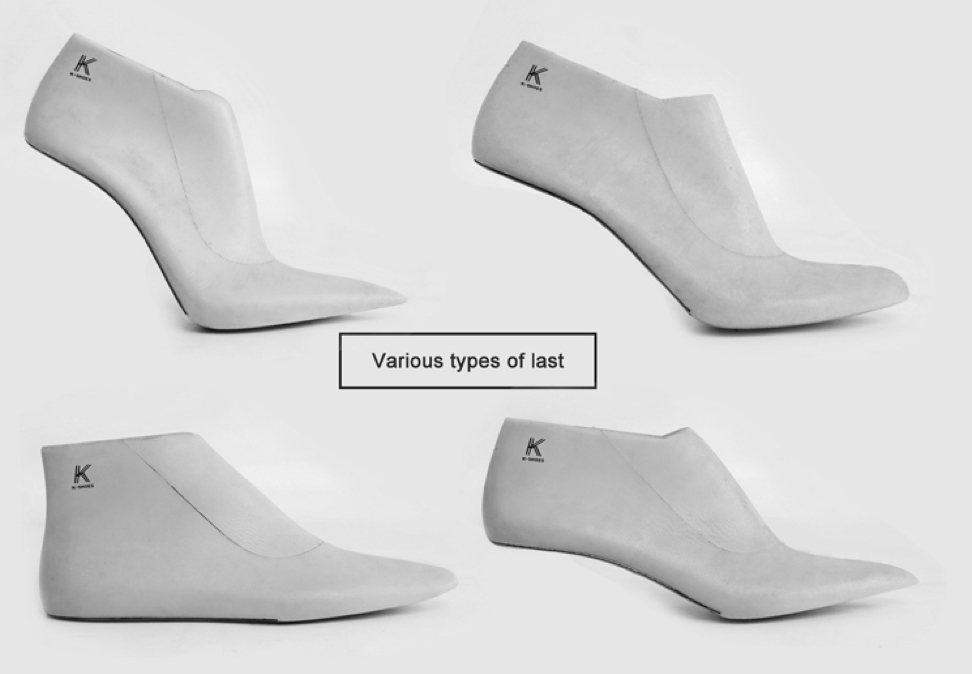

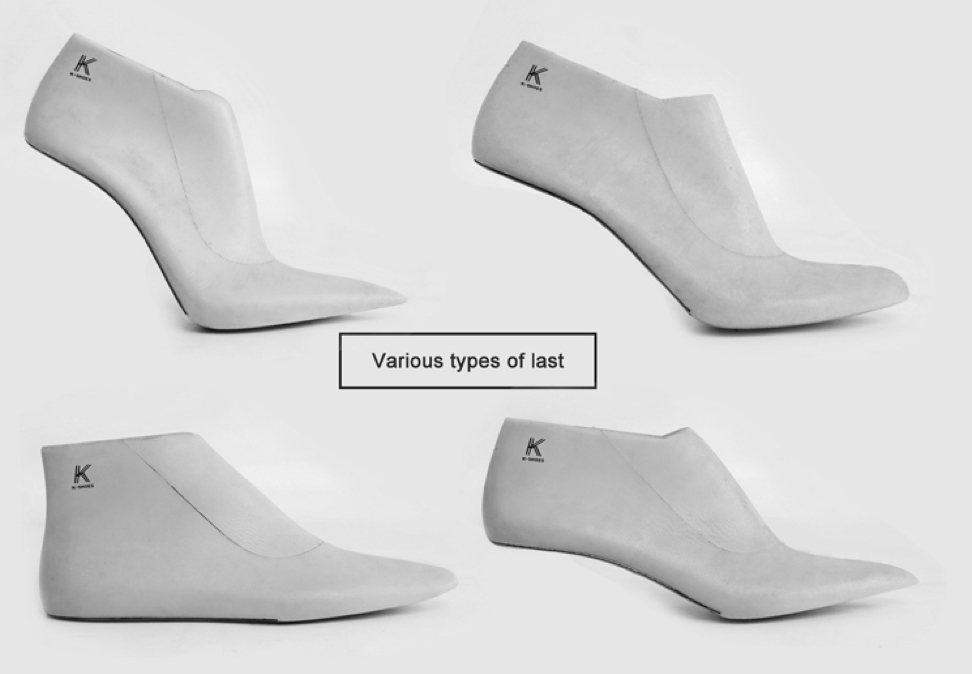

2. CATWALK SHOE LAST

Before a catwalk shoe can go into production it needs a last. This is the physical basis on how your catwalk shoes are made, because it is a mould that emulates a foot to give the shoe its shape. Traditionally these were carved from wood but now plastic and metal are also used. Every left and right catwalk shoe needs a last so its shape and size can be determined. But a last is no vaguely foot-shaped lump of wood and there are a number of things to be taken into account when creating one, including how a foot rolls when one walks and how this will affect factors such as heel height. Later in the catwalk shoe making process the last is placed inside the shoe so it can be modeled around it. It is used again once the catwalk shoe is almost finished to make sure the end fit matches the original design.

3. STAMPING AND SEWING

Partly due to the sheer number of pieces used to make one shoe, constructing footwear is a true craft. The pieces needed to make the catwalk shoe are cut from high quality leather then next in the catwalk shoes manufacturing process comes stamping. Now the catwalk shoe is referred to as a shaft and the pieces of leather that make it are stamped or marked. This is to avoid confusion when they are sewn together. Once the pieces have been stamped they are marked to indicate where eyelets need to be punched and where the points of the leather that will be stitched together to make a seam. The parts of the leather to be stitched are then thinned before the shaft is sent to the sewing department.

4. ASSEMBLING THE CATWALK SHOES

After the catwalk shoe is stitched, it begins the assembling process. Using three nails, the first step is to temporarily attach the insole below the catwalk shoe last. Then a rubber ridge is fixed to the insole, which makes stitching the shaft to the welt easier later. The shaft is laced and fitted over the last. It is then attached to the insole using hot glue and nails. The next step can take anything from 30 minutes to a fortnight. This is while the shaft and last are set aside to ensure the leather flawlessly assumes the last ‘s shape. It is time to stitch an approximately 3mm wide piece of leather, a welt, to the insole and the lining. This takes precision to ensure the welt is as close as possible to the shaft and the rubber ridge.

5. STEP INSOLES AND DECORATION

To address the problem that the catwalk shoe is not looking particularly stylish and its inner is still on the rough, a filler layer is added. To ensure comfort and movement the filler must be flexible so cork is normally used. This will even out the foundation for the insole which will be glued, and then securely stitched to the welt. Now the pins that were placed in the heel will be removed and the holes they have left in the leather sealed will be taken care of by any ornamental perforation. Or if the finish of the catwalk shoe is smooth, seam holes are carefully hidden through a procedure of ironing, dyeing and polishing. Next, the edge of the heel and its outsole are abraded and the visible part of the welt is decorated. The double seam is compacted next and the heel and tips of the sole are dyed. Last but not least, a half-insole with the brand’s logo is inserted and the catwalk shoe is carefully cleaned.

6. PACKAGE

Each and every catwalk shoe then undergoes a thorough final quality check. Then they are packaged and shipped to our designers, ready for a discerning customer to purchase and wear with pride. THE K HANDMADE FAMILY FACTORY has a variety of unconventional catwalk shoe boxes that can make an amazing catwalk shoe something even more remarkable. Many options in color, finishing, texture, shapes, sizes and magnetic lids are available.

THE K HANDMADE FAMILY FACTORY has audited by Sedex Members Ethical Trade Audit (SMETA), who is one of the most widely used ethical audit formats in the world. SMETA is not only used for our NY and London customers, but also used for Australia Myer and David Jones. These audits have gained popularity as brands and retailers seek to partner with suppliers that participate in SEDEX to ensure ethical trading and corporate social responsibility. We take labor rights and environmental responsibilities seriously at THE K HANDMADE FAMILY FACTORY. We stay on the cutting edge of this progressive mentality to fully implement socially conscious business practices.