Designers Solutions

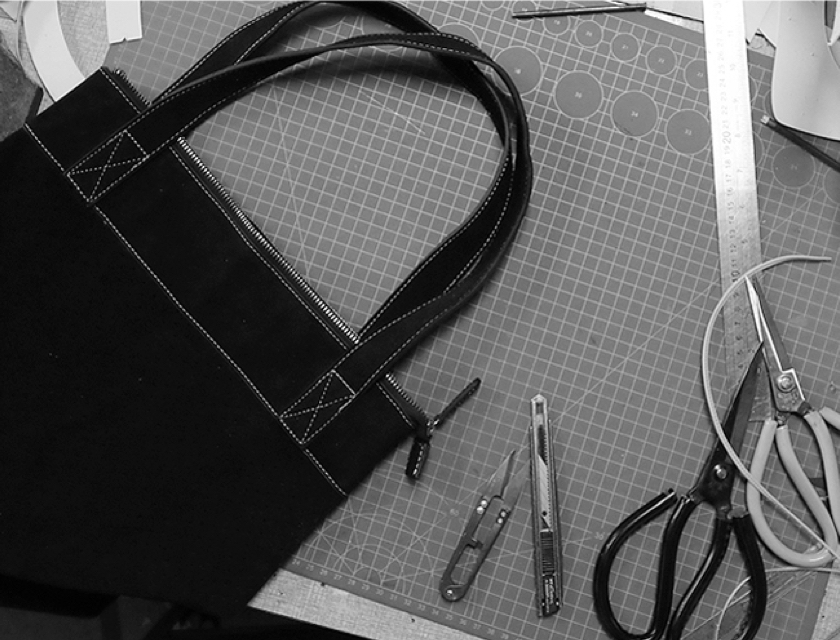

Handbag and Belt Inspection

Designers Solutions

Designers Solution

Hand and Belt Inspection

Intense competition, seasonality of markets, and continuous demands for innovation create a challenging environment for the manufacturing of bags around the world. Quality issues and delivery failures impact directly on the supply chain efficiency, profit margins, and brand’s reputation. Retailers must implement effective quality systems to meet delivery and safety standards, along with the expectations of end users.

Generally, handbag and belt manufacturing in China and Asia is facing great challenges now. The typical quality issues faced by brands and retailers are color transfer, mold, weak tear resistance, wrinkle marks caused by wrong packing method, and a host of other problems.

Quality control of bags and belts requires considerable on-site experience and close attention to detail. Inspectors of THE K HANDMADE FAMILY FACTORY verify the quality of handbag and belt, perform product function and safety tests, and assess compliance with product’s specifications and authorized samples. Our technical engineers customize our standard product checklist by adding the following specific tests to meet your quality requirements:

1. EXTERNAL PERFORMANCE ---SMELL, DIRTY STAIN, WRINKLE, SCRATCHES

Exhibitions is a good opportunity for buyers to see your collections. The exhibition organizers decide which fashion brand participate and they will work hard to protect the reputation of their event. You need to present yourself professional.

Exhibitions are a great place to meet trade and consumer press and promote your brand, so have a press pack available . Consumer shows also give your brand direct exposure to the public.

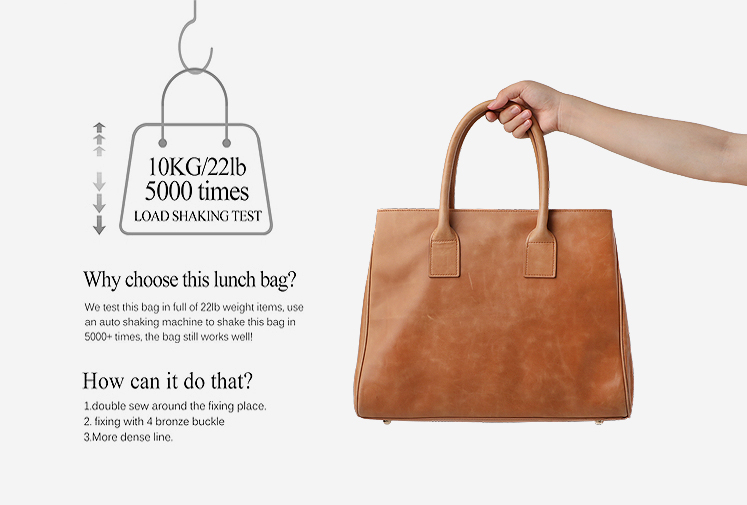

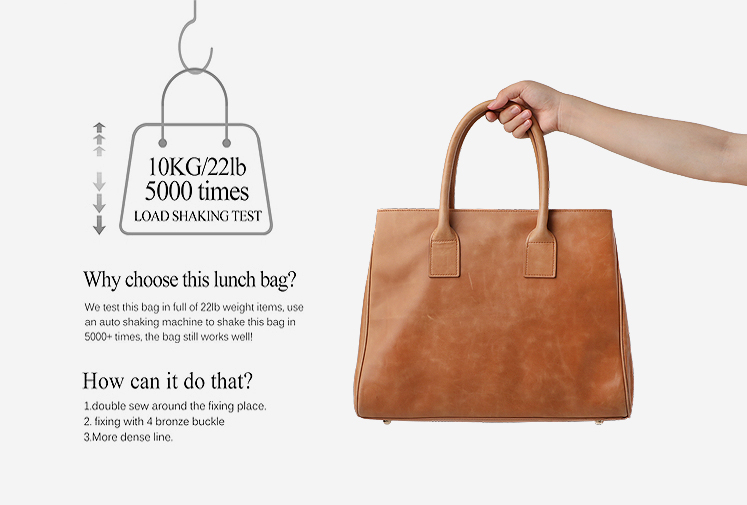

2. LOAD CAPABILITY

A bag’s ability to withstand a certain weight without falling apart is essential. The good news is that the load test used for this is easy to perform and doesn’t require special equipment. It’s also among the most standard tests for bags. The load test is performed on bags with handle, which could be envisaged in use, and then lifting them by the handle and setting them down. Any damage is assessed visually.

3. COLOR FASTNESS

The light fastness of a material describes its resistance to fading by light, in particular by the constant radiation of UV light. Among the types of leather, aniline-coloured porous leather is especially at risk of losing its original hue. The more engineered pigmented leather is less prone to this phenomenon. In the laboratory, there are devices that measure the fading sensitivity. Widely used is the Xenon test, which attempts to simulate sunlight and determines the resistance of dyeing under natural daylight on any type of leather.

4. TEAR RESISTANCE

This is done by placing the test sample into a tensile testing or universal test machine so that the section on one side of the fracture is pulled up and the section on the other side is pulled down. A steady load is then applied until the tear has propagated through the entirety of the sample and the two sections have been completely separated from one another. The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its ‘tear resistance’. This characteristic is particularly important to applications that use flexible materials that may suffer a partial rupture intentionally or otherwise.

5. SEAM STRENGTH

The manufacturing of leather products uses seam engineering to determine the best combination of sewing thread, stitch type, seam type, and stitch density to construct the end use structure. These four seam engineering variables contribute to a product being able to achieve the maximum sewn seam strength performance and structural integrity when cut pieces of fabric are joined together. This ability helps to keep the original structure and look of your bag and belt

6. WATER RESISTANCE

Knowing if your fabric is waterproof Is essential if you plan to use it in situations where it may come into contact with water. For THE K FAMILY FACTORY products, this water resistant finish provides a barrier against liquid absorption.

7. ABRASION RESISTANCE

Abrasion resistance refers to the ability of an adhesive to resist wearing due to contact with another surface. Wearing occurs when a hard rough surface slides across a softer surface, usually the adhesive material, causing the undesired removal of material from the surface.

8. ADHESIVE TEST ON LOGO AND LABEL

Ensuring logo and label are securely attached to products and packaging is a key element to quality branding for the company. Adhesion bond strength can be quantified in terms of peel strength, bonding strength, and sheer strength. Our test machines meet the requirements specified in many standard test procedures for constant-rate-of-extension and constant-rate-of-load machines. This allows the machines to be programmed to perform many unique testing procedures.

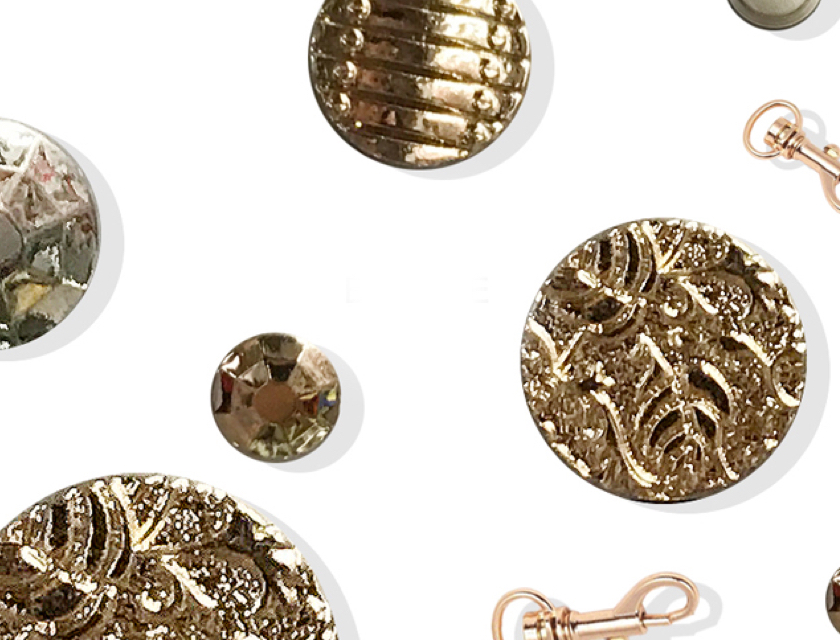

9. HARDWARE

From an assessment of the components of a belt for labeling purposes, color fastness (wet and dry rub fastness, and more) to tarnishing of buckles and metal components, THE K FAMILY FACTORY can test to all clients’ requirements to ensure the products are ‘fit for purpose’. Making sure they are attached correctly will avoid customer disappointment and damaged brand reputation.

10. RESTRICTED AND HAZARDOUS SUBSTANCES

All new products need to be monitored for the concentration of restricted substances including, lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr), polybrominated biphenyls (PBB) and polybrominated diphenyl ether (PBDE) and four different phthalates (DEHP, BBP, BBP, DIBP), which are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling. This test is to ensure that no product exceeds the RoHS limits of 0.1% or 1,000ppm (except for cadmium, which is limited to 0.01% or 100ppm) by weight of homogeneous material.

Plenty of handbag and belt are a sight to behold, but they must also provide long-lasting comfort. Handbag and belt design is nothing without a development process that’s centered on testing materials for quality and compliance regulations. That’s why THE K HANDMADE FAMILY FACTORY combines a creative, efficient handbag and belt design process with a testing mechanism to identify the best, most functional materials, making the handbag and belt development process complete. THE K HANDMADE FAMILY FACTORY verifies the quality, specifications, functions, and safety of your products and compliance of your products with relevant international standards.