Designer Solutions

Leather Test

Designer Solutions

Quality Inspection

Leather Test

Leather is a durable and flexible material created by tanning animal rawhide and skins. The most common raw material is cattle hide. It can be produced at manufacturing scales ranging from artisan to modern industrial scale. Leather is used to make a variety of articles, including footwear, automobile seats, clothing, bags, book bindings, fashion accessories, and furniture. It is produced in a wide variety of types and styles and decorated by a wide range of techniques.

THE K FAMILY FACTORY covers genuine leather like cowhide leather, sheepskin leather, suedes, patent leather, pony leather, etc. In order to correctly advertise and market your products as ‘genuine leather’, it is advised to verify your leather. Whether the leather in your product can be called genuine is determined by the extent of treatments that hides undergo in the tanning process. ‘Genuine leather’ labels can be applied to hide or skin that has been tanned to be rot-proof with its original fibrous structure intact. The hair or wool may or may not have been removed. Hide or skin which has been split into layers or segmented either before or after tanning is also considered genuine leather, provided that none of the surface is removed by buffing, snuffing or splitting.

Leather tests ensure your products meet country-specific quality and safety standards. They also mitigate the risk of costly recalls if your goods are found to be defective. The durability of hides depends on the treatments used in the tanning process. The following physical and chemical tests help you avoid common quality problems associated with leather goods.

1. Physical Testing

Physical testing includes whole leather appraisal, water resistance test, light & colour fastness test, tear strength test, abrasion resistance test, cold crack test and coatings, fasteners fatigue and zip quality test and stitching reinforcement strength.

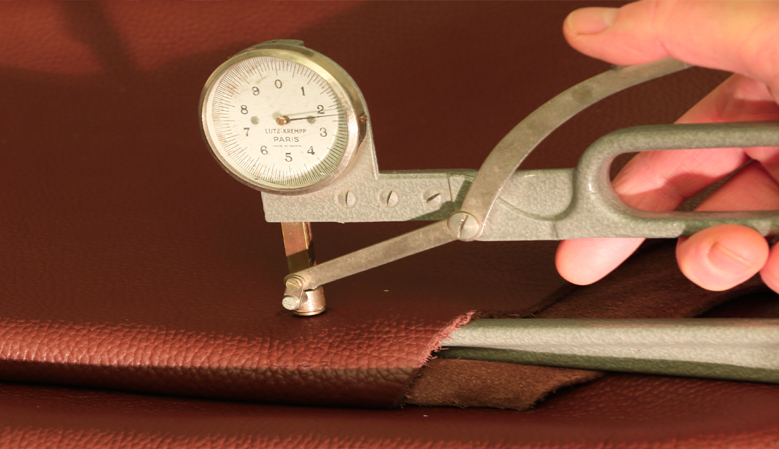

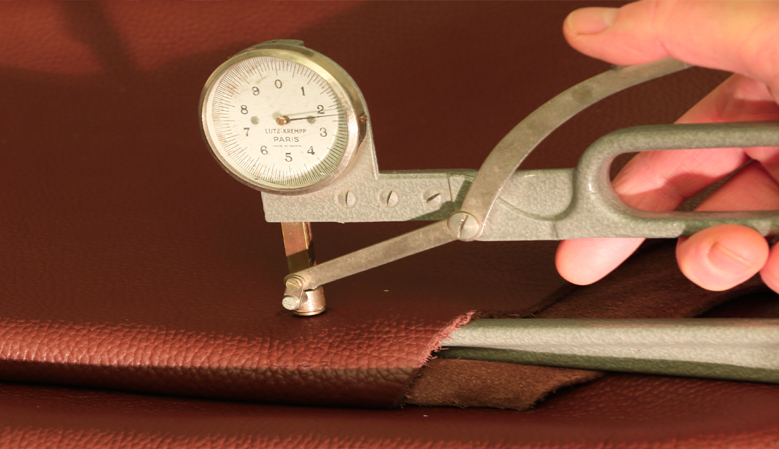

1.1 Whole Leather Appraisal --- thickness, density, uneven dying, smell, softness

This test method shall be used where precise dimensions are necessary for calculation of properties expressed in physical units. It applies to all types of leather of any tannage, and is valid for the whole leather and a test sample, which determines the apparent quality of the leather.

1.2 Water Resistance Test

Knowing if your leather product is waterproof is essential if you plan to use it in situations where it may come into contact with water. For THE K FAMILY FACTORY products, this water resistant finish provides a barrier against liquid absorption. All genuine leather needs to be protected. There is a range of treatments out there that can help make leather water resistant. One of the most common ways to keep leather protected from moisture is by applying wax such as Dubbin or Nikwax.

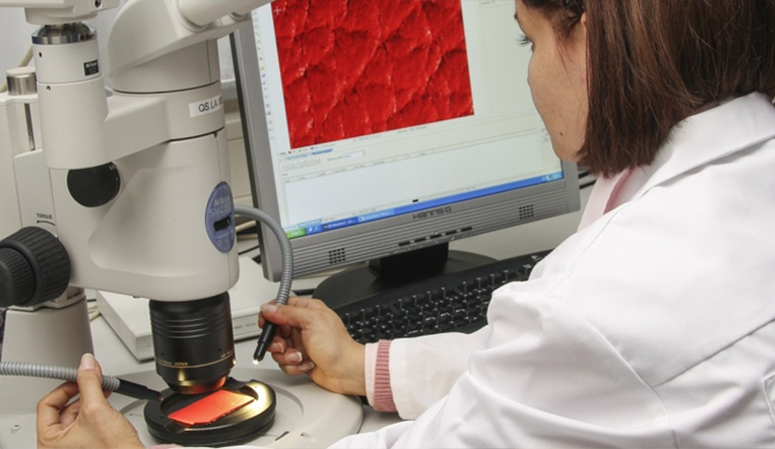

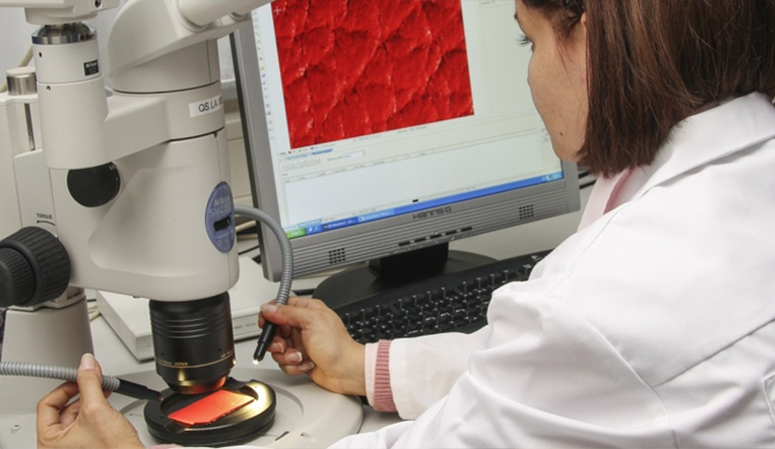

1.3 Light & Colour Fastness Test --- color variation, color migration

The light fastness of a material describes its resistance to fading by light, in particular by the constant radiation of UV light. Among the types of leather, aniline-coloured porous leather is especially at risk of losing its original hue. The more engineered pigmented leather is less prone to this phenomenon. In the laboratory, there are devices that measure the fading sensitivity. Widely used is the Xenon test, which attempts to simulate sunlight and determines the resistance of dyeing under natural daylight on any type of leather. This test determines the resistance of fading, bleeding, running of dyes or pigments, and color migration.

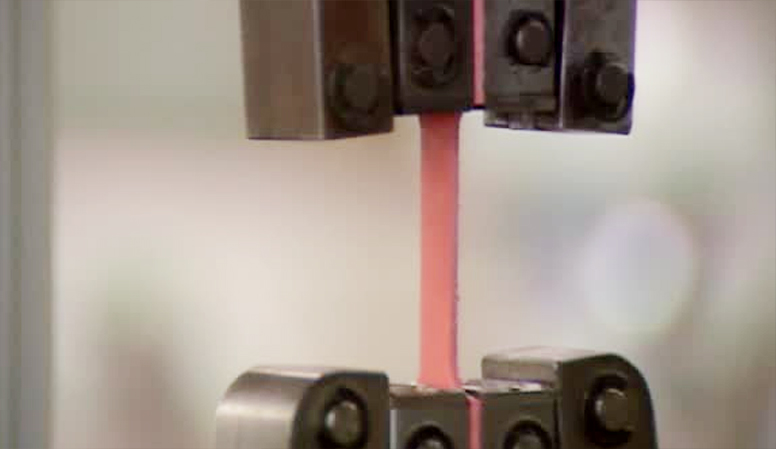

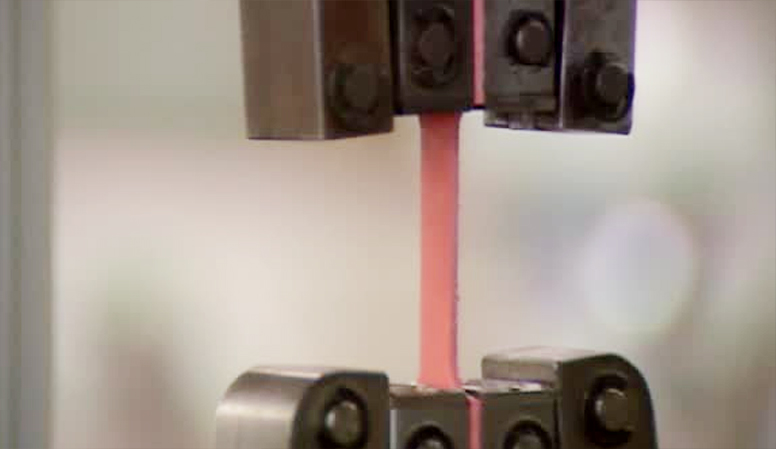

1.4 Tear Strength Test

This is done by placing the test sample into a tensile testing or universal test machine so that the section on one side of the fracture is pulled up and the section on the other side is pulled down. A steady load is then applied until the tear has propagated through the entirety of the sample and the two sections have been completely separated from one another. The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its ‘tear resistance’. This characteristic is particularly important to applications that use flexible materials that may suffer a partial rupture intentionally or otherwise.

1.5 Abrasion Resistance Test

Abrasion resistance refers to the ability of an adhesive to resist wearing due to contact with another surface. Wearing occurs when a hard rough surface slides across a softer surface, usually the adhesive material, causing the undesired removal of material from the surface.

1.6 Cold Crack Test and Coatings

It specifies a method for determining the cold crack temperature of surface coatings applied to leather. It is applicable to all leathers which have a surface coating and which can be easily flexed. To determine the temperature at which cracks may appear if chemical coated fabrics are left in the cold and then folded sharply.

1.7 Fasteners Fatigue and Zip Quality Test

From an assessment of the components of, color fastness (wet and dry rub fastness, and more) to tarnishing of buckles and metal components, THE K FAMILY FACTORY can test to meet all clients’ requirements to ensure the products are ‘fit for purpose’. Making sure they are attached correctly will avoid customer disappointment and damaged brand reputation.

1.8 Stitching Reinforcement Strength

The manufacturing of leather products uses seam engineering to determine the best combination of sewing thread, stitch type, seam type, and stitch density to construct the end use structure. These four seam engineering variables contribute to a product being able to achieve the maximum sewn seam strength performance and structural integrity when cut pieces of fabric are joined together. This ability helps to keep the original structure and look of your leather products.

2. Chemical Testing

Leather is a material made from the skin of an animal by tanning or a similar process. Before any leather products are placed on the market, there are legal obligations to be met to ensure they are ‘fit for purpose’. Chemical testing of leather can form part of a good production control system to ensure that performance requirements are met. Testing can also be used to indicate possible causes of problems or faults in the finished article. Our chemical testing includes restricted and hazardous substances, pH value, grease content and moisture test.

2.1 Restricted and Hazardous Substances

All new products need to be monitored for the concentration of restricted substances including, lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr), polybrominated biphenyls (PBB) and polybrominated diphenyl ether (PBDE) and four different phthalates (DEHP, BBP, BBP, DIBP), which are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling. This footwear test is to ensure that no product exceeds the RoHS limits of 0.1% or 1,000ppm (except for cadmium, which is limited to 0.01% or 100ppm) by weight of homogeneous material.

2.2 pH Value

This test method is designed to measure the pH of a distilled water extract of leather, which can also indicate the quality of the tanning or dyeing process used. This is considered to be a measure of the acidity or alkalinity of the leather. Excessive acidity or alkalinity may have a deleterious effect on the aging characteristics of leather. The pH value is measured on the a logarithmic scale of 0-14. Actual values can be less than 0 and higher than 14, but as a rule of thumb, the following ranges apply: Acidic at pH 1-7, Neutral at pH 7, Alkaline at pH 8 – 14. Higher levels of acidity could indicate that low-quality tanning procedures were used, and the leather will degrade prematurely. By contrast, an extremely alkaline result could indicate that dye fixation was performed poorly, and the leather’s color won’t last a long time.

2.3 Grease Content

Oils and fats give suppleness and softness to leather. The level of fatliquor (often referred to as the ‘grease content’) present in leather is controlled during the fatliquoring process. The final characteristics and performance of leather will be determined to some degree by the amount and type of fatliquors used. Poor control during this part of the production process may result in leather that is harder or softer than desired, or a leather that feels greasy. Another problem that can be attributed to the fatliquors is the possible formation of a fatty acid spue on the surface of the leather. This test method is used to measure the specific gravity of all oils and liquid fats that are used to soften leather, or that are used in products to soften leather. The specific gravity is one parameter that can be used to monitor the quality of these products.

2.4 Moisture Test

Moisture content is an important characteristic of leather and will change depending on the temperature and relative humidity of its surrounding environment. A moisture meter can be an invaluable tool for monitoring and testing the moisture content of leather to ensure a high-grade end product. By making rapid moisture checks in leather products throughout the tanning process, tanners can make sure that their goods are at the right moisture content to maximize quality and prevent issues such as mold or bacteria growth during storage.

Partnering with an independent inspection and testing entity enables you to identify and control quality concerns at the source whether inspection is conducted before, during and after production. Our inspectors have been well trained to inspect raw materials to be used, craftsmanship, production status, quantity, and more to ensure you will receive your leather products without unnecessary surprises.