Designer Solutions

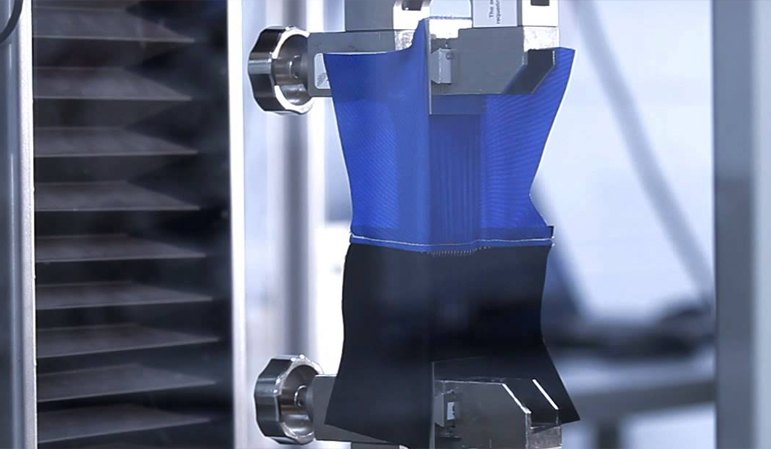

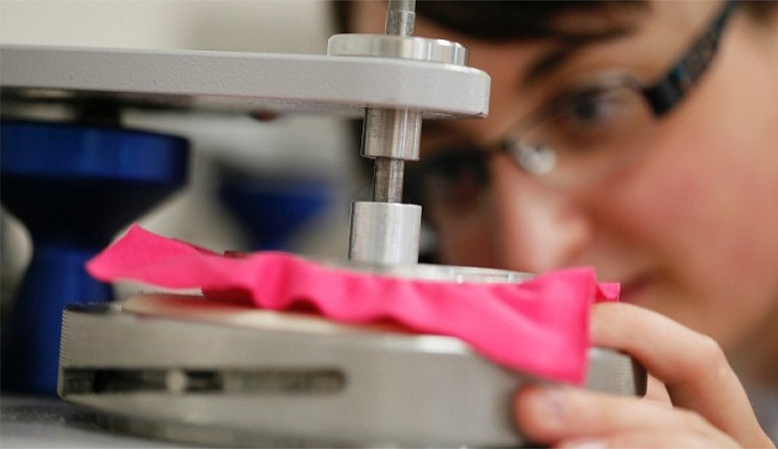

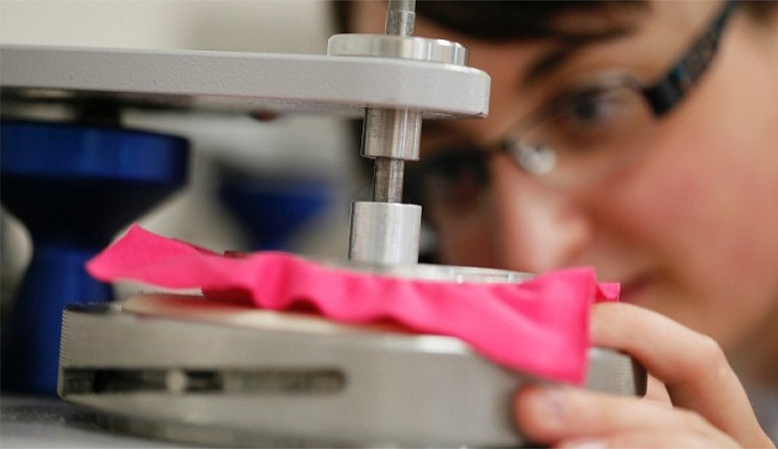

Fabric Test

Designer Solutions

Quality Inspection

Fabric Test

The footwear and accessories industry is becoming an increasingly competitive environment, thus differentiating products by quality is particularly important. Testing can be performed both to improve product quality and achieve compliance to international, regional or retailer specific standards. Our fabric testing provides a comprehensive review of the tests available for fabrics in footwear and accessories products. THE K FAMILY FACTORY ’s inspection and determination of incoming fabrics can effectively improve the authenticity rate of clothing.

Fabric is the most important raw material for footwear and accessories products. It incurs around 70% of the footwear and accessories products cost and nearly 100% of the exposed area. Fabric has to pass through maximum checks as the cost increases as it moves forward in the manufacturing process. A faulty fabric, if not screened out at the receiving phase, would involve further cutting, stitching, finishing, and packing costs. Therefore, it is ideal to check fabric at the source to save also on the transportation cost and time, in the case of faulty fabric. Another common practice, in local purchase, is to inspect the fabric right after it is received in the warehouse of footwear and accessories products manufacturing facility. A third party inspection may be involved where the prepared fabric has to be shipped to other countries.

Fabric testing includes two aspects: appearance quality and intrinsic quality. On the appearance, it mainly inspects whether the fabric has damage, stain, weaving defect, color difference and so on. Defects that affect appearance need to be marked with marks during inspection, and avoid use when cutting. The intrinsic quality of fabric mainly includes shrinkage, color fastness and gram weight, etc. THE K FAMILY FACTORY offers physical testing and chemical testing methods for fabric:

1. Physical Testing

Physical testing includes fabric color test, colorfastness, fabric weight, density and thickness test, yarn slippage test, fabric shrinkage test, tensile strength test, tearing strength test, bursting strength test, abrasion resistance test, and water resistance test.

1.1 Fabric Color Test

A standard way for testing fabric color is to check the Pantone color reference number as described by the customer. The dyed fabric is matched to the relevant Pantone reference to decide on whether to accept the prepared fabric lot. Footwear and accessories products manufacturers usually check fabric color against preapproved fabric swatches supplied by the customer.

1.2 Colorfastness to Light, Rubbing, Washing, Bleaching

Color fastness test is undertaken to measure the level of fading or bleeding that occurs on fabric with factors like washing, ironing, lights, rubbing etc. If colorfastness is good then item quality high and if poor fastness property then item quality is bad. So, colorfastness is an important factor for the buyer to justify whether the item is good or not.

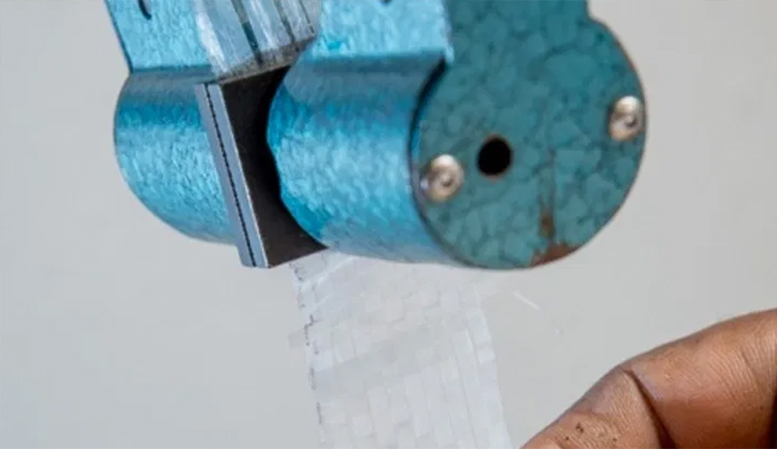

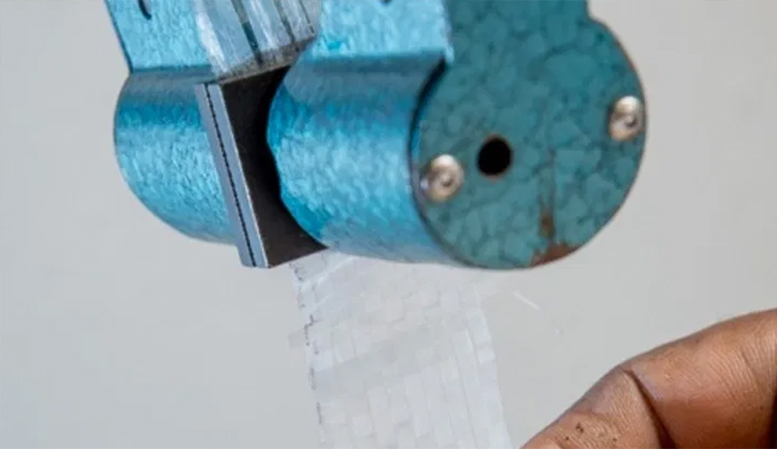

1.3 Fabric Weight, Density and Thickness Test

Fabric mass per unit area is a very important consideration in the selection of fabric for a particular end use. A common approach is to use a grams per square meter (GSM) cutter. The cutter prepares a circular specimen of diameter 113 mm. The weight of this specimen in grams, multiplied by a factor of a hundred, gives the weight (in grams) of the fabric in a square meter.

1.4 Yarn Slippage Test

One of the major issues in sewn fabrics is the yarn slippage. The fabrics in footwear and accessories products and other sewn products should exhibit sufficient resistance to yarn slippage along the seams. The test exists to determine the resistance to slippage of warp yarn over filling yarns, or filling yarns over warp yarns, using a standard seam.

1.5 Fabric Shrinkage Test

Fabric shrinkage is one of the prime considerations for the selection of fabrics in footwear and accessories products manufacturing. If the appropriate shrinkage is not considered, the footwear and accessories products may run short on the wearer’s body after washing. For that purpose, the shrinkage along both warp and weft is calculated and adjusted in product specifications in the cutting room. The stitched fabric may appear enlarged in some dimensions, but it adapts to the original customer requirements after washing. Similarly, it is important to measure fabric elongation.

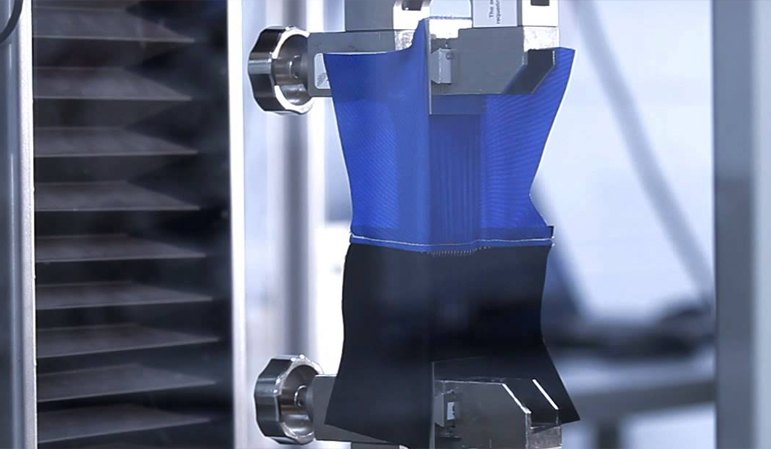

1.6 Tensile Strength Test

Fabric in footwear and accessories has to bear a number of forces throughout its performance life. Fabric, therefore, must satisfy the minimum level of strength to satisfy customer needs. For testing tensile properties, a test specimen of the fabric is clamped in the jaws of a tensile testing machine and a force is applied until the specimen breaks. The maximum amount of force exerted by the machine, recorded from the machine scale, gives the breaking force.

1.7 Tearing Strength Test

This is done by placing the test sample into a tensile testing or universal test machine so that the section on one side of the fracture is pulled up and the section on the other side is pulled down. A steady load is then applied until the tear has propagated through the entirety of the sample and the two sections have been completely separated from one another. The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its ‘tear resistance’. This characteristic is particularly important to applications that use flexible materials that may suffer a partial rupture intentionally or otherwise.

1.8 Bursting Strength Test

A specimen of fabric taken from footwear or accessories product is placed between grooved plates of the testing equipment and fastened by means of screws. A polished and hardened steel ball attached to a pendulum actuating clamp of the machine is forced through the fabric, at right angles to the fabric plane, until the rupture occurs. A common consideration for strength parameters of fabric is their bursting strength.

1.9 Abrasion Resistance Test

Abrasion resistance refers to the ability of an adhesive to resist wearing due to contact with another surface. Wearing occurs when a hard rough surface slides across a softer surface, usually the adhesive material, causing the undesired removal of material from the surface.

1.10 Water Resistance Test

Knowing if your fabric is waterproof is essential if you plan to use it in situations where it may come into contact with water. For THE K FAMILY FACTORY products, this water resistant finish provides a barrier against liquid absorption.

2. Chemical Testing

Considerable amounts of chemicals are involved in the manufacturing of fabric. It has become crucial to monitor and control the usage of chemical in the production cycle in accordance with the Restricted Substances List as many of the chemicals have been deemed to be harmful to the environment and to humans. Chemical Testing of THE K FAMILY FACTORY includes restricted and hazardous substances, fiber identification, and pH value.

2.1 Restricted and Hazardous Substances

The trend of green consumerism has extended to footwear and accessories products. All new products need to be monitored for the concentration of restricted substances including, lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr), polybrominated biphenyls (PBB) and polybrominated diphenyl ether (PBDE) and four different phthalates (DEHP, BBP, BBP, DIBP), which are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling. This test is to ensure that no product exceeds the RoHS limits of 0.1% or 1,000ppm (except for cadmium, which is limited to 0.01% or 100ppm) by weight of homogeneous material.

2.2 Fiber Identification

The fundamental structure of fabric is fiber. The identification of fiber is often the first task when an unknown fabric has to be analyzed. The chemical identification of fiber based on the solubility, stain and burning tests is presented. The determination of common fabric chemical qualities, such as pH and metals that are mostly concerned by wet fabric is discussed together with fabric whiteness and absorbency that are important for finished products.

2.3 pH Value

pH value is to test the acid and alkali contents remained in fabrics of footwear and accessories products. Fabrics which can directly contact with the skin has a relatively higher requirement on PH value. PH value will not make the skin itchy if controlled between weak acid or neutrality. This test method determines the pH of wet processed fabric. To make a quantitative determination, the chemicals which influence pH must be removed from the fabric specimen, collected as a water extract then accurately measured by a pH meter. The pH scale ranges from 0 to 14. A pH of 7 is neutral. The pH less than 7 is acidic. The pH greater than 7 is basic.

Partner with THE K FAMILY FACTORY for your fabric testing needs to assure compliance with changing governmental safety regulations and to meet increasing consumer demand for high-quality footwear and accessories products, while minimizing risk and protecting the interests of brands, retailers, suppliers and consumers.