Create Luxury Line>start new shoe line

PRODUCTION

Fine Shoe Production

From Material to Masterpiece - Flexible Manufacturing with THE K FAMILY TEAM

Once the fine prototype is approved, THE K FAMILY TEAM seamlessly transitions into shoe production, offering a uniquely flexible manufacturing model tailored to the needs of prestige brands, from emerging designers to established houses. We are proud to support both small batch production and large-scale orders, with no minimum order quantity (MOQ) for initial collaborations, making us the ideal partner for new designers and established prestige brands alike. Our comprehensive shoe making process covers every stage, from meticulous material sourcing to flawless packing, ensuring consistent fine quality and exceptional craftsmanship in every pair.

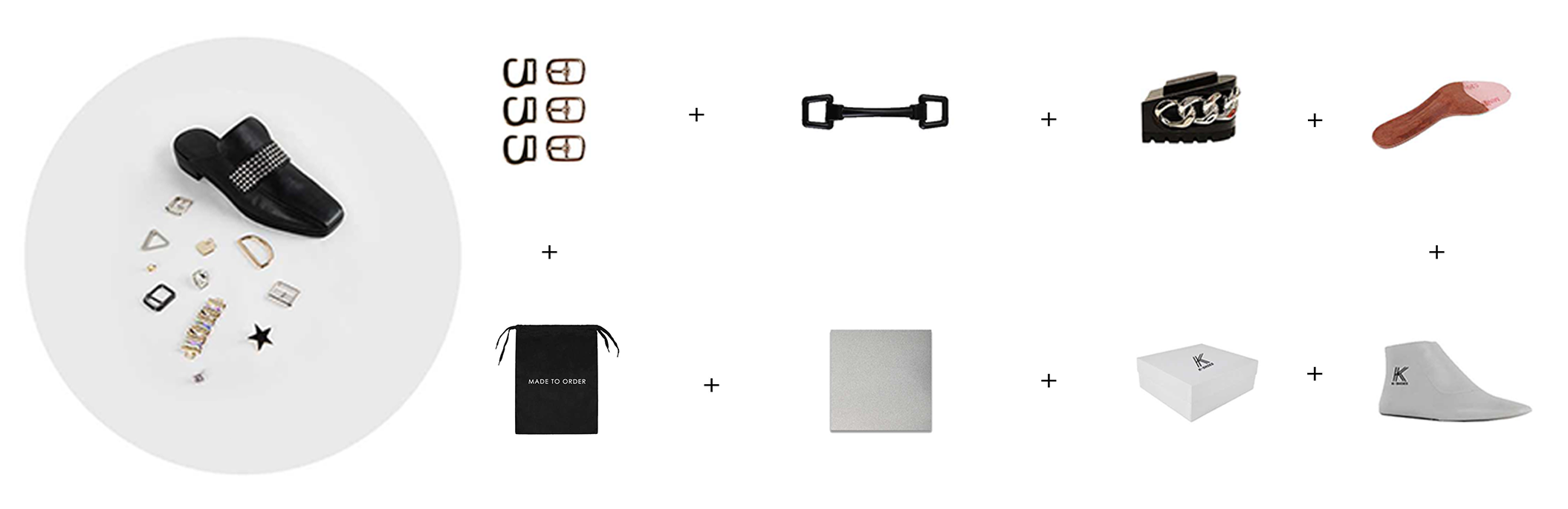

1.Material Procurement and Premium Component Sourcing – The Foundation of Quality Production:

The shoe production process begins with securing the finest premium materials and components, mirroring the meticulous sourcing undertaken for prototypes. THE K FAMILY TEAM leverages its established global network to ensure a consistent supply of premium quality materials:

Premium Material Ordering and Inventory Management:Based on confirmed production orders, our procurement team efficiently orders the required quantities of premium materials – leathers, fabrics, outsoles, heels, linings, and hardware – from trusted suppliers. We maintain meticulous inventory management to ensure timely material availability for production schedules.

Incoming Material Quality Control (Production Batch Inspection):Upon arrival at our factory, all production batches of premium materials undergo rigorous incoming material quality control This ensures that every roll of leather, fabric, and box of components meets our stringent quality standards and matches the approved specifications of the fine prototype. We check for color consistency, material integrity, and any potential defects before materials enter the production line.

Premium Component Stock Preparation (Organized for Efficiency):Once materials pass quality control, they are carefully organized and prepared for the shoe making Leather is sorted and prepped for cutting, fabrics are rolled and inspected, and components are inventoried and staged for efficient access during assembly. This meticulous preparation streamlines the production flow and minimizes delays.

2. Fine Shoe Component Cutting and Preparation – Precision at Scale:

Translating the approved shoe patterns into precisely cut components is a critical step in scaling up from prototype to production. THE K FAMILY TEAM utilizes a combination of advanced technology and skilled craftsmanship for efficient and accurate cutting:

Pattern Digitization and CAD/CAM Integration (Digital Cutting Technology):Approved shoe patterns are digitally stored and integrated with our Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. This digital workflow ensures precise pattern replication and optimizes material utilization for efficient mass production cutting.

Automated Die Cutting for Volume Production (High-Volume Cutting):For high-volume production runs, automated die-cutting machinery is employed to precisely and rapidly cut large quantities of shoe components. This technology ensures consistent accuracy and speeds up the component cutting process for efficient mass production.

Hand Cutting for Intricate Details and Small Batches (Artisan Cutting for Fine Shoes):For intricate fine shoe designs, delicate materials, or small batch production runs, skilled artisans utilize hand-cutting techniques. This allows for greater flexibility, precision in handling complex shapes, and meticulous attention to detail, preserving the artisan cutting quality essential for fine footwear.

Component Skiving, Edge Finishing, and Reinforcement (Production Level Preparation):Following cutting, all shoe components undergo production-level preparation, including skiving edges for smooth seams, consistent edge finishing for durability and aesthetics, and application of reinforcements to ensure structural integrity across the entire production run.

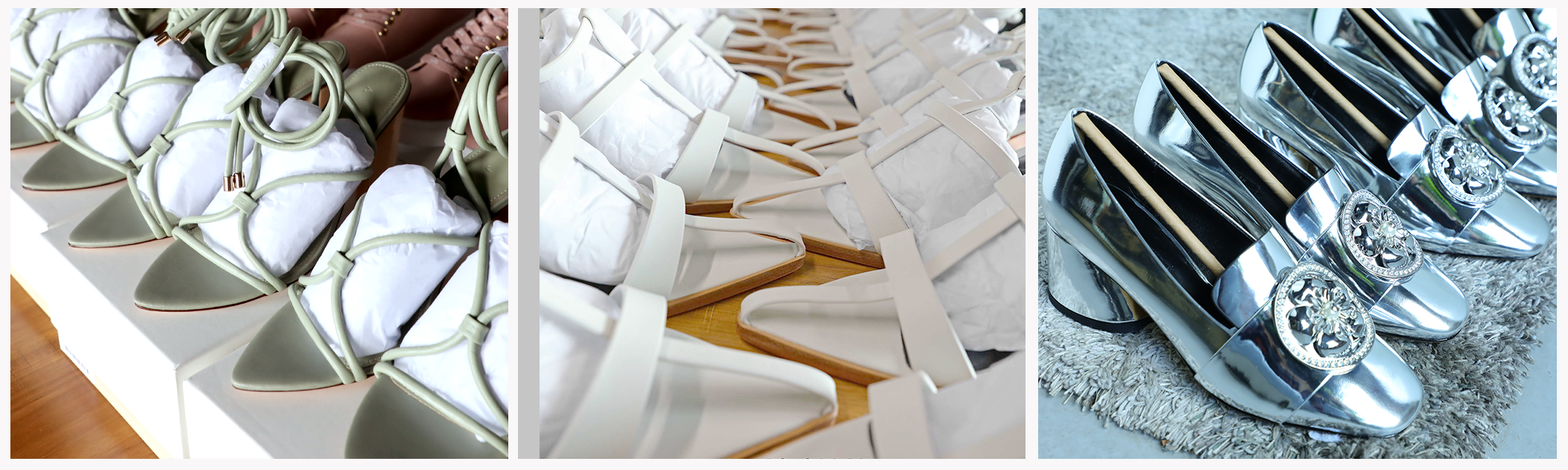

3. Fine Shoe Assembly – Scaling Artisan Craftsmanship:

THE K FAMILY TEAM seamlessly scales the artisan craftsmanship of prototype assembly to efficient shoe production, maintaining fine quality even at higher volumes. Our flexible production lines are designed to accommodate both small batch production and larger orders:

Modular and Adaptable Assembly Lines (Flexible Production Lines):Our shoe assembly lines are modular and adaptable, allowing us to efficiently configure production for different fine shoe styles and order volumes. This flexibility is key to accommodating both small batch production for new designers and larger runs for established prestige brands.

Specialized Assembly Stations (Style-Specific Assembly):Assembly lines are organized into specialized stations, each dedicated to specific shoe making processes – upper stitching, lasting, outsole attachment, heel mounting, and finishing. Stations are tailored to the unique construction requirements of different fine shoe styles, ensuring focused expertise at each stage.

Skilled Assembly Line Workers (Trained in Fine Techniques):Our assembly line workers are highly skilled and rigorously trained in fine shoe making production They possess the dexterity and attention to detail required to maintain the highest standards of craftsmanship even in a mass production shoes environment.

In-Process Quality Control (Real-Time Quality Checks):Quality control is integrated throughout the shoe assembly line. In-process inspections are conducted at each station to identify and rectify any deviations from quality standards in real-time. This proactive approach minimizes defects and ensures consistent fine quality throughout the entire production run.

Adaptable Production Volume (Small Batch to Large Scale):THE K FAMILY TEAM is uniquely positioned to handle production volumes ranging from small batch production (catering to new designers and exclusive capsule collections with no minimum order quantity) to large-scale orders for established prestige brands. Our scalable shoe manufacturing capabilities provide unparalleled flexibility.

4. Fine Finishing and Final Quality Control – The Pursuit of Perfection in Every Pair:

The final stages of shoe production are dedicated to achieving the flawless finish and uncompromising quality that define fine footwear. Our shoe finishing line and rigorous final quality inspection processes ensure every pair leaving our factory meets the highest standards:

Automated and Hand Finishing Techniques (Fine Finishing Methods):The shoe finishing line combines automated processes for efficiency with hand-finishing techniques for meticulous detailing. Automated machinery may be used for tasks like edge trimming and buffing, while skilled artisans perform hand-polishing, detailed cleaning, and application of specialized finishes to achieve the desired fine

Detailed Final Quality Inspection (100% Inspection Rate):Every single pair of fine shoes undergoes a comprehensive final quality inspection before packing. This 100% inspection rate ensures that no shoe with even minor imperfections leaves our factory. Inspectors meticulously check stitching, material integrity, finishing details, hardware attachment, and overall aesthetic presentation against the approved fine prototype

Premium Packaging and Branding Integration (Brand-Specific Packing):Approved fine shoes are carefully prepared for packing. This includes final cleaning, inserting shoe trees or forms to maintain shape, and wrapping each shoe in protective tissue or cloth. We seamlessly integrate your brand’s premium packaging materials, ensuring that each pair is presented in packaging that reflects your brand’s identity and enhances the unboxing experience for the consumer. We can accommodate brand-specific packing requirements, including custom boxes, dust bags, and branded inserts.

Order Fulfillment and Global Shipping (Efficient Logistics):Packed fine shoes are prepared for order fulfillment and global shipping. Our logistics team ensures efficient and secure handling of finished goods, coordinating with shipping partners to deliver orders to boutiques, retailers, or direct-to-consumer distribution centers worldwide, ensuring timely and reliable delivery.

5. Flexible Order Quantities – No Minimum, Scalable to Large Volumes:

THE K FAMILY TEAM differentiates itself by offering unparalleled flexibility in order quantities, making fine shoe production accessible to a wider range of brands:

No Minimum Order Quantity (MOQ) for New Designers (New Designer Support):We understand the challenges faced by new designers and emerging prestige brands. Therefore, we offer no minimum order quantity (MOQ) for initial collaborations. This allows new designers to launch their collections without the financial burden of large minimum orders, making fine shoe production attainable from the outset and providing crucial new designer support.

Small Batch Production for Exclusive Collections (Limited Edition Production):For brands seeking exclusivity and limited editions, we excel in small batch production. We can efficiently produce smaller, highly curated runs of fine shoes, allowing for greater design experimentation and catering to niche markets or special collections.

Scalable Production for Growing Brands (Large Volume Shoe Manufacturing):As your prestige brand grows, THE K FAMILY TEAM can seamlessly scale production to meet increasing demand. Our infrastructure and processes are designed to handle large-volume shoe manufacturing while maintaining consistent fine quality and timely delivery.

Adaptable to Evolving Brand Needs (Flexible Manufacturing Partner):Our flexible manufacturing model allows us to adapt to the evolving needs of your prestige brand. Whether you require small batch production for initial launches, scaled-up volumes for wider distribution, or a mix of both, THE K FAMILY TEAM provides a truly adaptable and supportive shoe production

In Summary:

THE K FAMILY TEAM offers a complete and highly flexible fine shoe production solution, from material procurement to packing. Our commitment to fine quality, combined with our ability to accommodate small batch production with no minimum order quantity and scale to large volumes, makes us the ideal shoe manufacturing partner for new designers and established prestige brands seeking exceptional craftsmanship, unparalleled flexibility, and a seamless production experience. We are dedicated to bringing your fine shoe designs to life, regardless of order size, with the same meticulous attention to detail and unwavering commitment to excellence that defines THE K FAMILY TEAM.