Create Luxury Line>create bag line

PRODUCTION

Bag & Belt PRODUCTION MAKING -

Precision Craftsmanship at Scale with THE K FAMILY TEAM

THE K FAMILY TEAM excels in bag & belt production making, seamlessly blending artisan techniques with efficient manufacturing to uphold luxury quality. We handle both small batch production and large volume orders for prestige brands and high-end designers, from premium material procurement to final finishing, ensuring exceptional craftsmanship and design integrity in every piece. For luxury bag belt designers seeking a factory known for quality and precision in bag & belt production making, THE K FAMILY TEAM is the ideal manufacturing partner.

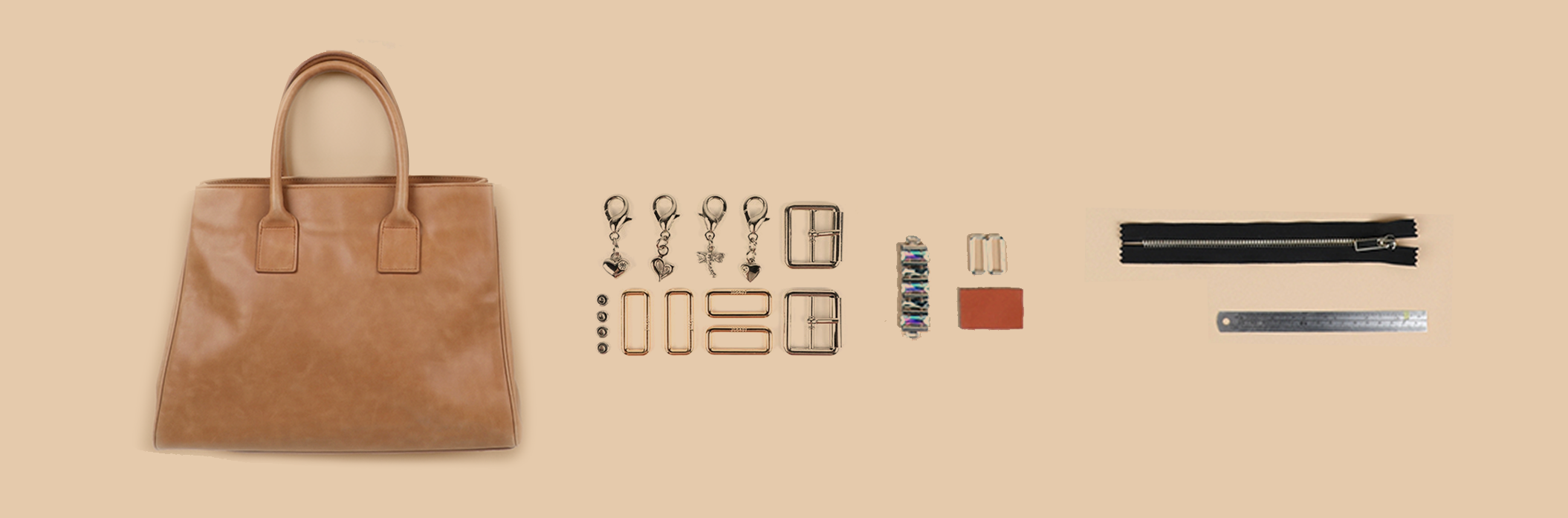

1.Bag & Belt Material Procurement and Premium Component Sourcing – The Foundation of Fine Leather Goods

The bag & belt production making begins with meticulous premium leather sourcing bags and component selection, which is absolutely crucial for fine leather goods. THE K FAMILY TEAM leverages its established global network to secure the finest resources, ensuring a robust luxury material supply chain and ethical material procurement factory.

Luxury Leather Selection and Procurement:We maintain a premium leather supply chain, sourcing luxury leathers from top tanneries worldwide. Our selection process is rigorous, focusing on only the highest grades: full-grain, top-grain, and fine leather belts materials, and exotic skin sourcing bags (ethically verified). This premium leather sourcing bags guarantees exceptional quality, texture, and durability for our ethical material procurement factory. Our premium leather supply chain reflects our commitment to exceptional leather.

High-End Hardware Procurement:Our high-end hardware procurement belts ensures that every buckle, zipper, clasp, and embellishment meets the stringent demands of luxury design. We procure designer hardware accessories from trusted suppliers who specialize in crafting components for luxury accessories. This includes buckles meticulously crafted from fine metals, exceptionally durable premium zipper sourcing bags, elegant clasps with secure mechanisms, and bespoke, brand-custom hardware options to perfectly align with your brand’s unique aesthetic. This high-end hardware procurement belts strategy elevates both the aesthetic appeal and the functional reliability of our luxury bags and belts.

Quality Linings and Trims:We select fine fabric linings bags like silk, and microfiber for bag interiors. For edges, we use premium edge paint belts for a lasting finish. Durable stitching thread accessories of the highest strength ensures structural integrity for all our fine leather goods.

Rigorous Incoming Material Quality Control:All materials undergo luxury material inspection factory Premium materials and quality component sourcing accessories face stringent incoming material quality control. Our teams perform meticulous luxury material inspection factory checks, inspecting leather, hardware, and linings. This quality assurance leather goods process ensures only the finest materials pass our component testing accessories and enter bag & belt production making, upholding luxury quality.

2.Bag & Belt Component Cutting and Precision Preparation – Accuracy at Scale

Accurate component cutting is vital for our bag & belt production. THE K FAMILY TEAM combines advanced technology and artisan skill for precision leather cutting bags and component preparation belts:

CAD/CAM Digital Pattern Cutting:Approved patterns are digitized and integrated with CAD/CAM systems for digital pattern making bags and automated leather cutting belts. CAD/CAM digital pattern cutting optimizes material use and ensures consistent dimensions for mass production bags and mass production belts. This technology is key to our precision component cutting factory.

Automated Die Cutting for Volume Production:For high volume bag component cutting, automated die-cutting machinery provides rapid, accurate cutting of large volumes. Automated die cutting ensures efficiency and consistency for mass production belt components and bags in our efficient cutting factory.

Hand Cutting for Intricate Designs and Small Batches:For complex designs or small batch cutting accessories, skilled artisans use artisan leather cutting bags. Hand cutting leather goods allows meticulous precision and preserves artisan craftsmanship for handcrafted belt components and bespoke cutting services.

Component Skiving, Edge Finishing, and Reinforcement:Following cutting, components undergo component preparation belts, including leather skiving factory processes for smooth seams, edge finishing techniques bags for aesthetics and durability, and component reinforcement belts for structural integrity. These are crucial steps in preparation for assembly.

3.Bag & Belt Assembly Line Production and Artisan Techniques – Blending Efficiency with Craft

THE K FAMILY TEAM blends bag assembly line production and belt making process factory efficiency with artisan bag assembly in bag & belt making to maintain luxury accessory assembly quality across all volumes. Our lines suit small batch bags and scalable production bags:

Modular and Adaptable Assembly Lines:Our flexible bag production line and adaptable belt manufacturing allow efficient reconfiguration for diverse styles and volumes. This flexible bag production line suits small batch bag manufacturing and large scalable accessory assembly.

Specialized Assembly Stations for Bag & Belt Types:Lines are organized into specialized assembly stations for specific processes like belt construction stations and handbag assembly stations, tailored for style specific production in wallet assembly lines and other product types.

Skilled Assembly Line Workers with Artisan Training:Our bag assembly line production relies on trained bag makers and skilled belt artisans trained in efficient and luxury craftsmanship assembly line Our expert stitching team maintains luxury accessory assembly standards in scalable production bags.

In-Process Quality Control at Every Stage:Real time quality checks bags and in line inspection belts are integrated throughout assembly. Proactive quality control during assembly ensures defect minimization production and consistent luxury quality in bag & belt production making.

Adaptable Production Volume from Small Batch to Large Scale:We handle volumes from small batch bag manufacturing (with no MOQ options) to large volume belt production. Our scalable accessory factory provides flexibility for diverse brand needs in luxury accessory assembly.

4.High-End Hardware Attachment and Refined Embellishment – Elevating Design Details

Luxury hardware attachment bags and embellishments define luxury bags & belts. THE K FAMILY TEAM dedicates expertise to this stage of bag & belt production making:

Precise Hardware Setting and Secure Attachment:Artisans specialize in precise hardware setting bags and secure buckle attachment belts. We ensure flawless placement and robust fixing of luxury buckle suppliers belts and designer hardware accessories for aesthetic appeal and functional longevity with durable hardware integration accessories.

Hand-Finishing of Hardware Details:Meticulous hand-finishing hardware enhances luxury. This includes polishing hardware bags, finishing buckles belts, and refining metal accessories to a luxury finish hardware factory

Expert Embellishment Application:For embellishments, our luxury accessory assembly line features artisans skilled in precise embellishment bags and decorative detail belts. Their hand applied embellishments expertise ensures flawless integration of intricate details and luxury trim application accessories.

Quality Inspection of Hardware and Embellishments:Rigorous hardware quality check bags and embellishment inspection belts ensure perfect placement, secure attachment, and flawless finish. We verify luxury standard hardware and precise final detail verification accessories application for fine quality.

5.Fine Finishing and Final Quality Control – Perfection in Every Piece of Leather Goods

Final stages ensure flawless finish and quality in bag & belt production making. Our bag finishing line factory and final quality inspection leather goods processes guarantee excellence:

Dedicated Bag & Belt Finishing Line:We use a specialized bag finishing line factory and fine accessory finishing line, combining automated and luxury finishing methods bags with hand finishing for detail. Artisans perform hand-polishing and premium edge paint belts touch-ups for a luxury aesthetic in our automated and hand finishing factory.

Comprehensive Final Quality Inspection:Every piece undergoes final quality inspection leather goods before packing. This 100 percent inspection bags ensures no imperfections leave our factory. Inspectors perform detailed quality check belts against luxury accessory quality assurance standards and final detail verification accessories.

Premium Packaging and Brand Integration:Approved pieces are prepared for premium packaging, including cleaning, wrapping, and placement in custom packaging bags and branded boxes belts. We integrate your brand’s packaging, meeting brand specific packing factory requirements for luxury presentation accessories.

Order Fulfillment and Global Shipping:Packed items are prepared for order fulfillment factory and global order fulfillment factory with efficient logistics bags. Our team ensures secure international shipping belts and door to door delivery accessories, guaranteeing timely delivery of your fine leather goods.

In Summary:

THE K FAMILY TEAM delivers a complete bag & belt production making process, from premium material procurement to packing shoes factory level packaging and global shipment. Our commitment to luxury quality and capacity for small batch production and scalable accessory factory volume makes us the premier bag & belt manufacturer for prestige brands and high-end designers. We bring your visions to life with precision, artisan craftsmanship, and excellence, making us your ultimate high-quality bag and belt factory.